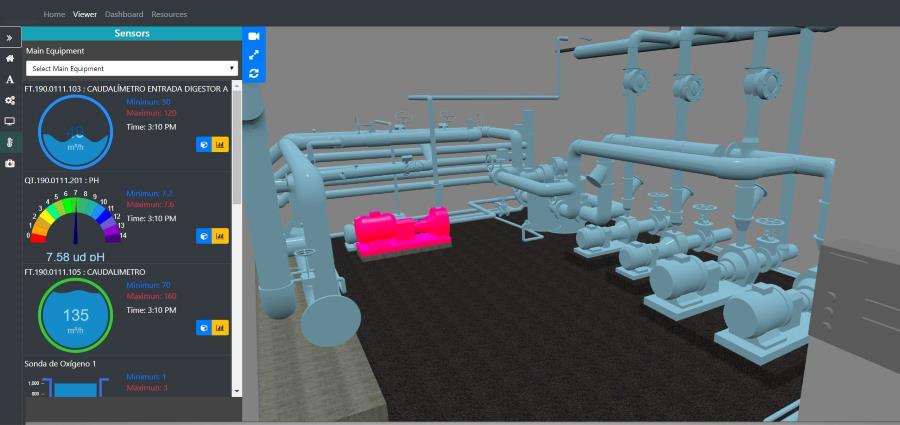

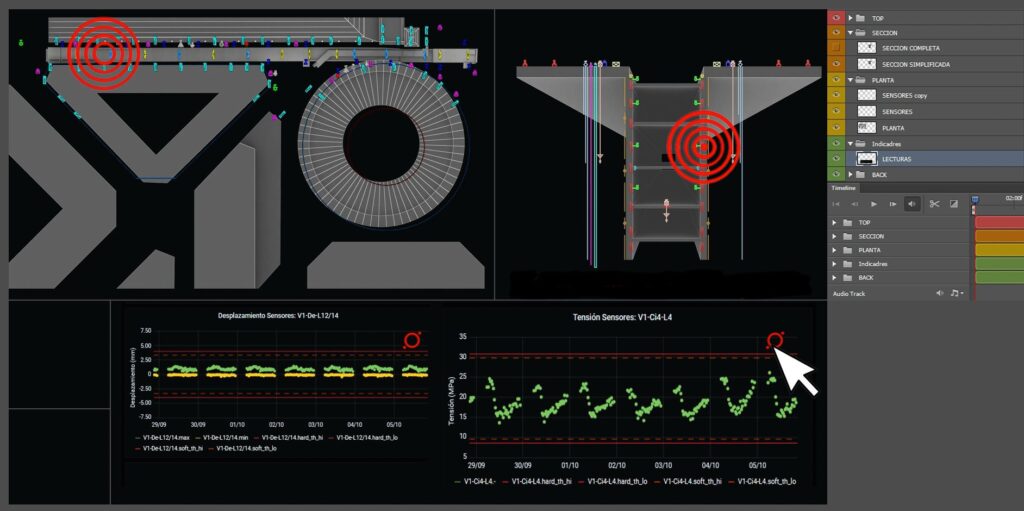

A digital twin is a digital replica of a physical asset, system, or process. To create one, technologies such as cameras and sensors—like 3D laser scanners—are used. This digital model not only represents the physical object but also interacts with it through data analysis, simulations, and predictions powered by artificial intelligence and the Internet of Things (IoT).

The applications of a digital twin are vast and incredibly useful, including:

- Real-time asset monitoring.

- Simulation of favorable and unfavorable scenarios to optimize processes.

- Predictive maintenance to prevent failures.

- Visualization and analysis for informed decision-making.

Applications of Digital Twins

Develop a digital twin have a significant impact across various sectors where proactive actions are essential to avoid risks caused by a lack of foresight. These sectors include:

- Construction and Infrastructure: Optimizing projects and maintaining smart buildings.

- Manufacturing: Improving efficiency in production lines.

- Energy and Utilities: Managing power grids and maintaining energy plants.

- Transportation and Logistics: Simulating routes and optimizing fleets.

- Healthcare: Modeling medical devices and hospital systems.

Developing a Digital Twin

The creation of a digital twin is based on three key pillars:

- Data Collection: Using IoT sensors and digital sources.

- 3D Modeling: Employing advanced tools like BIM methodology to accurately represent the asset.

- Real-Time Connectivity: Feeding the model with dynamic data for simulations and predictive analysis.

How Digital Twins Are Enhanced with BIM

Combining BIM methodology with digital twins unlocks unique benefits:

- Operational Efficiency: BIM provides precision in design and construction, while the digital twin optimizes the usage and maintenance of assets.

- Cost Reduction: Lower maintenance expenses through predictive analysis and efficient resource management.

- Data-Driven Decision-Making: BIM lays a solid foundation for design, while the digital twin delivers real-time insights for strategic decisions.

- Sustainability: Reduces environmental impact by maximizing asset performance and minimizing waste.

At Acero Estudio, we are experts in BIM consulting and digital twin creation, offering comprehensive solutions for projects of any scale. We optimize your processes and help you improve efficiency with the most advanced technology on the market. Contact us today, and let’s start improving your efficiency and transforming the way you manage projects!